AI Predictive Maintenance in Manufacturing (2025): Ultimate Guide to Boost Efficiency & Cut Costs

Table of Contents

Introduction: The Manufacturing Revolution is Here

In today’s hyper-competitive industrial landscape, unplanned downtime is the enemy. Every minute a machine is offline, it costs manufacturers thousands in lost revenue, productivity, and repair expenses. For decades, maintenance strategies have been reactive (fix it when it breaks) or preventive (fix it on a schedule). But what if you could predict failures before they happen? This is the promise of AI-powered predictive maintenance (PdM), a revolutionary approach that is transforming the factory floor.

What is AI-Powered Predictive Maintenance?

AI-powered predictive maintenance uses machine learning (ML) algorithms and data from Industrial IoT (IIoT) sensors to continuously monitor the health of equipment in real-time. Instead of relying on fixed schedules, PdM analyzes patterns in data (like temperature, vibration, and pressure) to forecast potential failures with incredible accuracy. This allows maintenance teams to intervene at the perfect moment—right before a problem occurs, maximizing uptime and resource efficiency.

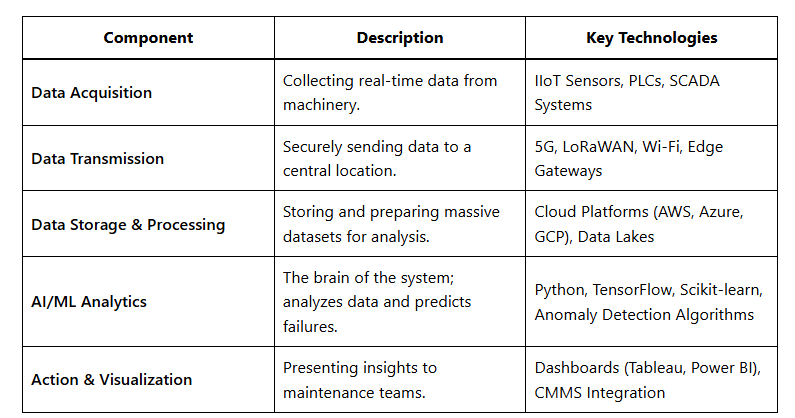

The Core Components of a PdM System

Building a successful PdM system involves several key technological layers working in concert.

Key Benefits: Moving Beyond Reactive Maintenance

The shift from reactive to predictive maintenance offers substantial, measurable benefits that impact the entire value chain.

1. Maximized Uptime and Productivity

By predicting failures, you can schedule maintenance during planned downtime, drastically reducing unexpected stops. According to a McKinsey report, AI-driven predictive maintenance can reduce downtime by up to 50%.

2. Reduced Maintenance Costs

Instead of replacing parts on a conservative schedule, you replace them only when needed. This extends the lifespan of components and reduces waste, cutting overall maintenance costs by 10-40%.

3. Improved Safety

Failing equipment can create hazardous conditions for workers. By identifying potential issues early, PdM helps create a safer working environment.

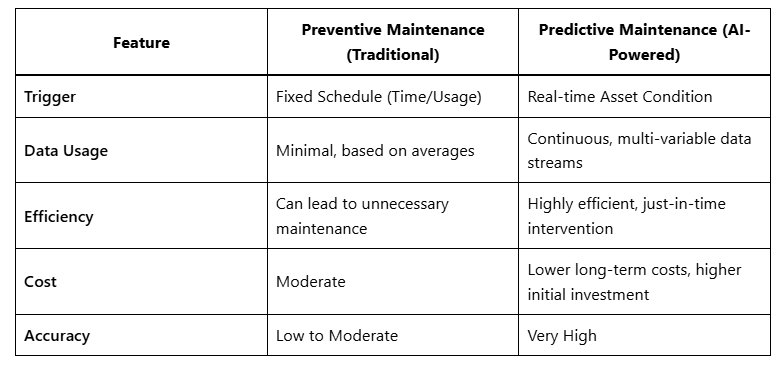

Comparison: Predictive vs. Preventive Maintenance

Conclusion: The Future is Predictive

AI in predictive maintenance is no longer a futuristic concept; it’s a competitive necessity. By leveraging data and machine learning, manufacturers can transform their maintenance operations from a costly, reactive function into a proactive, value-driving powerhouse. Embracing this technology is key to building the smart, resilient, and efficient factory of the future.

Frequently Asked Questions (FAQs)

What kind of data is needed for predictive maintenance?

You typically need sensor data like vibration analysis, thermal imaging, oil analysis, and acoustic analysis, as well as historical maintenance records.

How long does it take to implement a PdM system?

A pilot project can be up and running in 3-6 months. A full-scale implementation across a large facility can take over a year, depending on the complexity and existing infrastructure.

Is predictive maintenance only for large enterprises?

No. With the rise of cloud computing and more affordable IoT sensors, AI-powered PdM solutions are becoming increasingly accessible for small and medium-sized manufacturers as well.

Add a Comment