Edge AI Predictive Maintenance 2025: The Ultimate Guide to Preventing Failures & Boosting Efficiency

Imagine a world where critical industrial machinery rarely fails unexpectedly—where maintenance shifts from costly, reactive scrambles to proactive, precisely timed interventions. This is the promise of predictive maintenance, supercharged by Edge AI. On this page

Table of Contents

Why Predictive Maintenance + Edge AI, and Why Now?

Predictive maintenance (PdM) reduces unplanned downtime, extends asset life, and improves workforce productivity. In 2022, the global PdM market was valued at $7.85B and is projected to reach $60.13B by 2030. In parallel, edge computing—essential for real-time analytics close to machines—is estimated at $227.80B in 2025 and set to hit $424.15B by 2030. The takeaway: PdM and Edge AI are converging into a powerful, mainstream pillar of Industry 4.0.

This shift isn’t just technological—it’s cultural. Enterprises are moving from “fix-it-when-it-breaks” toward intelligent, data-driven foresight that prevents failures before they happen.

From Reactive to Predictive: The Evolution

Traditional strategies were either reactive (fixing after failure) or preventive (fixed schedules regardless of condition). PdM emerged as the smarter alternative, using IoT sensor data (vibration, temperature, pressure, acoustics) to forecast failure windows and trigger maintenance at the optimal moment.

Why Edge AI Is a Game-Changer

Classic cloud-only analytics add latency and bandwidth costs. Edge AI moves inference to the shop floor—right next to the assets—so you get:

- Real-time response: Act in milliseconds for time-sensitive assets.

- Lower bandwidth: Send summaries, not raw high-frequency streams.

- Resilience: Keep operating during intermittent connectivity.

- Privacy & compliance: Sensitive operational data stays on-prem.

Edge AI Hardware: Choosing the Right Platform

Matching hardware to workload is critical. Below is a vendor-neutral snapshot of leading options for PdM.

NVIDIA Jetson: Powering Complex Analytics

Ideal for deep learning and rich computer vision. Modules like AGX Orin deliver up to hundreds of TOPS, enabling real-time multi-camera inference and multi-sensor fusion. Strong CUDA/TensorRT/JetPack ecosystem. Trade-off: higher power draw and cost.

Google Coral (Edge TPU): Lean & Inference-Ready

Optimized for quantized TensorFlow Lite models with very low power (often 2–4W). Great for battery-powered IoT nodes performing efficient anomaly detection at the edge. Trade-off: best for inference, not training or full-precision models.

FPGAs (e.g., Xilinx Kria): Ultra-Low Latency Customization

Reconfigurable logic for deterministic, ultra-low-latency pipelines—perfect for high-speed inspection or closed-loop control. Power-efficient with excellent throughput. Trade-off: steeper development curve. Feature Comparison

| Feature | NVIDIA Jetson | Google Coral (Edge TPU) | FPGAs (e.g., Xilinx Kria) |

|---|---|---|---|

| Primary Strength | High-performance GPU; complex models & vision | Ultra-efficient TFLite inference at low power | Hardware-level customization; deterministic latency |

| Typical Power | ~5–60W (model-dependent) | ~2–4W | <10W typical |

| Best For | Complex vision, robotics, multi-sensor fusion | Embedded IoT, battery devices, dedicated inference | High-speed control, custom algorithms |

| Ecosystem | CUDA, TensorRT, JetPack | TensorFlow Lite, Python APIs | Toolchains; domain-specific IP cores |

| Cost | Medium–High | Low–Medium | Medium–High (dev effort) |

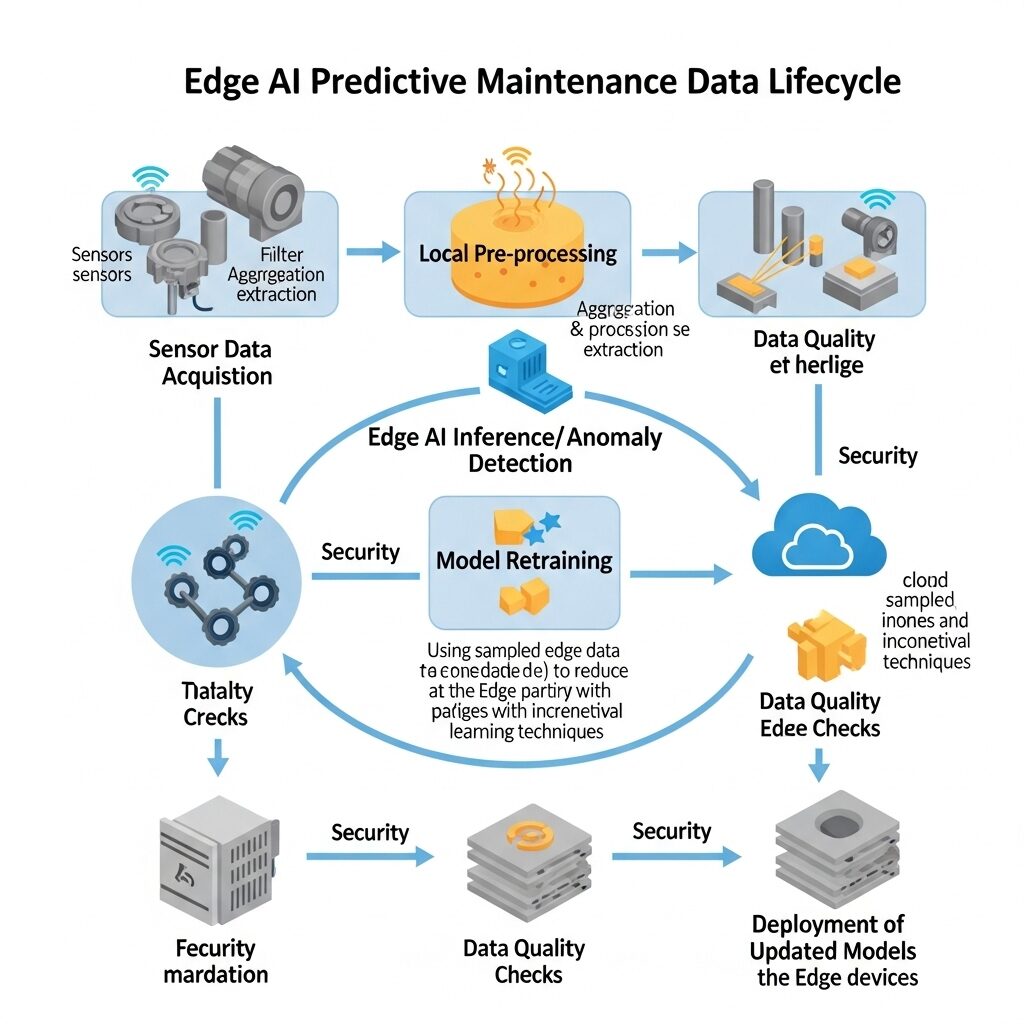

The Data Journey: From Sensor to Insight

1) Acquisition & Edge Pre-Processing

IIoT sensors capture vibration, temperature, pressure, and acoustics. At the edge, preprocess streams via denoising, normalization, windowing, and feature extraction (e.g., FFTs, spectral bands, kurtosis). This shrinks payloads and boosts signal quality for accurate inference.

2) Model Training, Deployment & Re-Training

Train centrally (cloud/on-prem), then optimize for edge (quantization, pruning, TensorRT compilation). Push signed models to devices securely. Monitor performance and schedule continual re-training to prevent model drift. Techniques like federated learning keep data local while aggregating updates for global improvements.

Implementation Architectures & Best Practices

Decentralized Edge Processing

For remote or critical sites, let devices operate autonomously: detect anomalies, trigger alarms, and even execute safe shutdowns without cloud dependency.

Hybrid Edge–Cloud

Most deployments blend real-time edge inference with cloud analytics for fleet trends, model life-cycle management, and historian storage. Integrate with SCADA, MQTT, and OPC UA for seamless data flow.

ML Models That Power Smarter Maintenance

Deep Learning for Early Anomaly Detection

- Autoencoders: Learn “normal” signatures; high reconstruction error flags anomalies.

- Isolation Forests: Unsupervised outlier detection effective for multivariate sensor data.

- 1D CNNs / LSTMs: Capture temporal and spectral patterns in vibration/acoustic streams.

Reinforcement Learning for Prescriptive Actions

Move from “predictive” to prescriptive by recommending optimal actions—adjust setpoints, scheduling, or load balancing—to maximize uptime, quality, and energy efficiency.

TCO & ROI: The Financial Case

Typical cost components include sensors, edge devices, connectivity, integration, licenses, training, and ongoing support. What matters: the savings outpace the spend—often within 24–36 months. Business Impact Benchmarks

| Benefit Area | Typical Improvement with PdM & Edge AI | Impact |

|---|---|---|

| Unplanned Downtime | 25–75% reduction | Avoids costly production halts (can reach $150,000/hour in discrete manufacturing) |

| Maintenance Costs | 20–40% reduction | Less emergency work, better spares planning |

| Equipment Uptime | 10–20% increase | More throughput without new capex |

| Asset Lifespan | 20–40% extension | Defers replacement and major overhauls |

| Energy Consumption | Up to 40% reduction | Lower OPEX, greener operations |

Common Pitfalls & Troubleshooting

Data Quality & Integrity

- Calibrate sensors; validate ranges and units at ingestion.

- Detect and handle drift, dropouts, and sensor misalignment.

- Add edge-side data QA: outlier filtering, missing value strategies.

Model Drift & Lifecycle

- Track precision/recall/F1 in production, not just in lab.

- Automate re-training with recent, representative samples.

- Version models; enable safe rollback if KPIs degrade.

Connectivity & Latency

- Buffer locally with store-and-forward patterns.

- Design for degraded networks; allow autonomous operation.

- Choose ruggedized edge devices for harsh environments.

Cybersecurity at the Edge

- Device identity & access: Per-device certificates, strong auth, least-privilege roles.

- Secure updates: Signed firmware and models; remote update channels with rollback.

- Data protection: Encrypt in transit and at rest; segment OT from IT networks.

- Real-time threat detection: Edge analytics to spot abnormal traffic or behavior.

What’s Next: The Intelligent, Autonomous Edge

As models get lighter and silicon grows more efficient, expect self-optimizing assets: PdM that not only predicts failure but automatically tunes parameters to avoid it. The convergence of AI, edge computing, and IIoT will keep accelerating smart manufacturing.

Actionable Tips for Adoption (Checklist)

- Start Small, Scale Smart: Pilot on a high-criticality asset with clear pain points.

- Invest in Data Quality: Robust sensor strategy + edge pre-processing pipelines.

- Match Hardware to Workload: Jetson for complex vision; Coral for low-power inference; FPGA for deterministic latency.

- Plan Model Lifecycle: Monitoring, re-training, A/B model rollout, and secure updates.

- Prioritize Security: Security-by-design across devices, data, and networks.

Ready to Deploy Edge AI Predictive Maintenance?

Get an implementation blueprint tailored to your assets, data, and ROI goals.

FAQs

What is Edge AI in predictive maintenance?

Edge AI runs inference on or near the equipment to detect anomalies and predict failures in real time, reducing latency and bandwidth while improving resilience and privacy. Which hardware is best for Edge AI predictive maintenance?

It depends: NVIDIA Jetson for complex vision/workloads, Google Coral for ultra-efficient TFLite inference, and FPGAs for deterministic, ultra-low-latency pipelines. How fast is the ROI?

Many manufacturers see payback in 24–36 months, driven by lower downtime, extended asset life, reduced maintenance costs, and energy savings. Do I still need the cloud?

Yes—for fleet analytics, long-term storage, and model lifecycle management. Most teams use a hybrid edge-cloud architecture. How do I handle model drift?

Continuously monitor KPIs, collect recent data for re-training, and automate safe model updates with version control and rollbacks.

[…] guiding users through techniques like cognitive behavioral therapy. Furthermore, advancements like Edge AI for predictive maintenance could potentially be applied to predict patterns of community distress or resource needs, allowing […]

[…] serve humanity positively. The discussion around these technologies, including those focused on Edge AI for predictive maintenance, highlights the diverse ethical considerations in various AI […]

[…] guiding users through techniques like cognitive behavioral therapy. Furthermore, advancements like Edge AI for predictive maintenance could potentially be applied to predict patterns of community distress or resource needs, allowing […]